COFFEE TABLE PRODUCTION PROCESS

The natural stone coffee table production process is based on carefully processing natural stones and shaping them in accordance with the coffee table design. The procedure requires aesthetics, durability and precision. Natural Stone Coffee Table In the production process, natural stone must first be produced. Natural Stone Production process is a comprehensive process that requires a lot of labor.

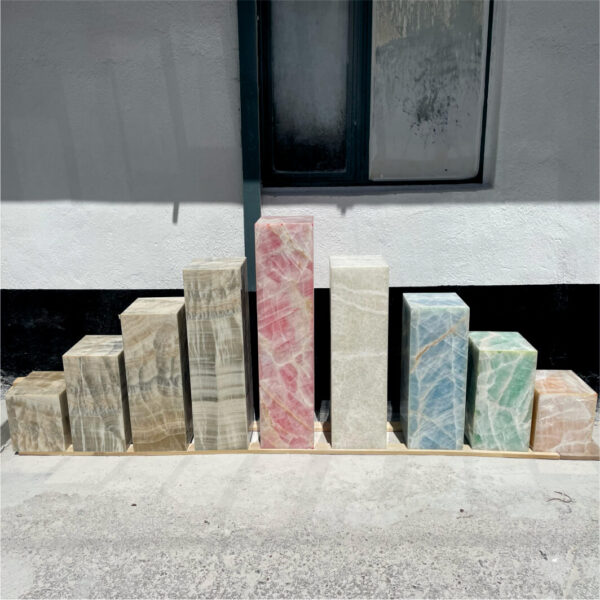

NATURAL STONE PRODUCTION PROCESS

The first step in the production process of natural stones such as marble, travertine, granite, onyx and basalt is to determine the location where the stone will be located. This is done by geological surveys and examination of local quarries. High quality stone reserves are preferred for production. The quality, density, color and structure of the stone are evaluated at this stage. In quarries, large machines, explosives or special drilling machines are used to dislodge rocks. Stone is usually mined in large blocks. These blocks are then made portable. Additionally, the surface of the stone is cut to obtain the desired properties. The cutting process ensures that the stone is removed in smooth blocks without damaging its natural structure. Large blocks of stone are transported by transport vehicles after being quarried. Mined stone blocks can be stored for a period of time before processing. This helps in further processing the stone into the desired size and shape. Blocks are processed by machines in stone workshops. These machines are used to shape the stone into the desired shape, smooth its surface and cut it. Additionally, stones can be polished to obtain a smooth surface. Natural stone can be cut into different shapes. Properties such as the durability of the stone, color, vein structure and density are checked.

Some stones can be tested for their resistance to certain conditions. Stones to be used especially in the construction and decoration sector can be approved with quality certificates. This guarantees the durability and safety of the stone. Processed stones are packaged appropriately according to their intended use. Delicate stones are wrapped with protective materials to prevent damage during transportation. The stone is transported to be shipped to the end user or construction site. During shipment, transport vehicles are carefully selected to ensure the stones arrive properly.

Natural stones are used in construction, interiors, exteriors, flooring, facades or as decorative elements.

The natural stone production process is achieved through the combination of high-tech machines and expert workforce. Additionally, the process may vary depending on the type of stone and the characteristics of the surface to be processed.

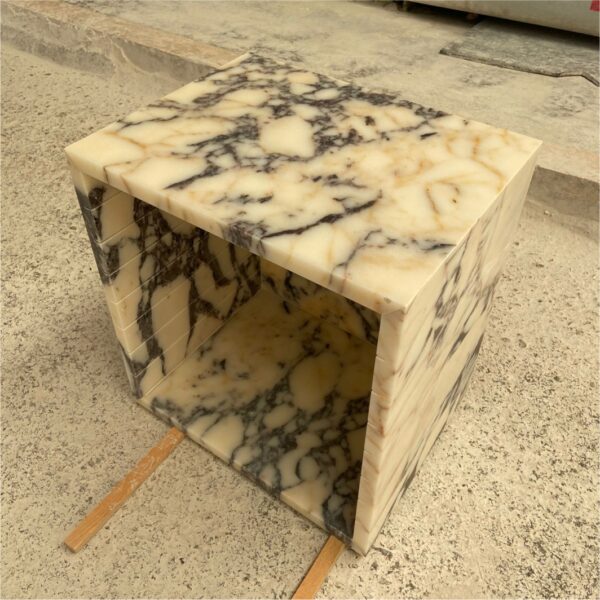

NATURAL STONE COFFEE TABLE PRODUCTION PROCESS

The Natural Stone Coffee Table production process begins with the production of Natural Stone. Among the Natural Stones obtained from quarries and brought to the factory, the ones suitable for the design and usage area are selected. The homogeneity of the stone’s color, vein structure and durability are checked. Stones with defects or cracks are eliminated. The cut stones are sliced and shaped to suit the coffee table dimensions.

Natural Stone Coffee Table Shaping and Design Processes

Depending on the design of the coffee table, special engravings are made on the edges of the stone (rounding, corner chamfer, straight cut, etc.). Decorative patterns or carvings can be made on the upper surface of the coffee table. CNC machines are frequently used at this stage. Rough surfaces are smoothed with special stone sandpaper. The stone surface is treated with special chemicals and polishing machines to give it a shiny appearance. A matte, semi-matte or full gloss finish can be achieved. A waterproof coating or a special resin is applied to increase resistance to stains and scratches.

Assembly

If legs are required in accordance with the shape of the coffee table, coffee table legs made of metal, wood, marble or other materials are selected in accordance with the design. The legs are cut, assembled and coated to prevent rust or corrosion (e.g. powder coating or chrome plating). The natural stone table is combined with the coffee table legs with special connection devices, screws or adhesives. If the entire coffee table is made of natural stone, an application is made accordingly. It is checked whether the coffee table is stable and balanced.

Quality Control and Shipment

After production, the coffee table is examined for surface smoothness, measurement accuracy and durability. Aesthetic defects and assembly errors are eliminated. The stone surface is protected against breakage with bubble wrap, styrofoam or wooden cases. The coffee table is packaged in a way that it will not be damaged during shipment and directed to the logistics unit for delivery. Since each stone in natural stone coffee table production has its own unique vein structure and texture, each coffee table has a unique appearance. This process requires both technology and craftsmanship to ensure aesthetics and durability together.